The Problem of Extreme Wear and Tear

Industries like mining, construction, and heavy machinery face a relentless challenge—abrasion and impact wear. Equipment and structural components in these sectors are constantly exposed to harsh environments, leading to rapid degradation, high maintenance costs, and frequent downtime. Standard steel often fails to withstand these tough conditions, resulting in inefficiency and elevated operational expenses.

This is where a specialized solution is crucial—a material that can endure the pressure without giving in.

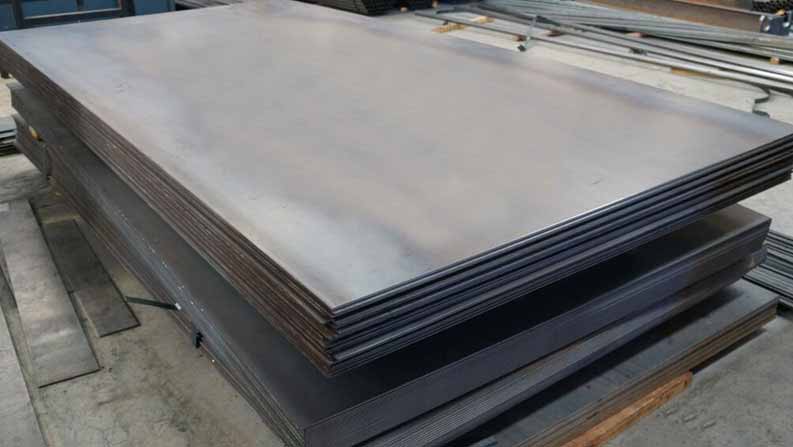

2. Rockstar 450 Plate :

The Rockstar 450 Plate is a wear-resistant steel plate designed for extreme abrasion and high-impact applications. Manufactured with a superior alloy composition and heat-treated to a high hardness level (~450 BHN), this plate offers a unique combination of toughness, strength, and durability.

Produced by credible manufacturers, Rockstar 450 is engineered to outperform conventional steels in hostile working conditions, making it a go-to material for wear-prone equipment.

3. Advantages of Rockstar 450 Plate

Exceptional Hardness: With a nominal hardness of 450 Brinell, it significantly resists wear and tear.

Superior Toughness: Despite its hardness, the plate maintains ductility and impact resistance.

Extended Service Life: Reduced need for frequent replacements or repairs, lowering overall costs.

Good Weldability and Machinability: Easy to process with standard methods, enabling flexible fabrication.

Consistent Quality: Uniform mechanical properties across the plate ensure predictable performance.

4. Real-Life Uses of Rockstar 450 Plate

Mining Equipment: Used in dump truck bodies, excavator buckets, and crushers.

Construction Machinery: Ideal for bulldozer blades, concrete mixers, and loaders.

Material Handling: Applied in conveyor systems, chutes, and hoppers.

Agricultural Tools: Used in plowshares and tillage equipment.

Recycling Plants: Common in shredders and liners subjected to high abrasion.

5. Problem Solving & Outcome of Using Rockstar 450 Plate

By incorporating Rockstar 450 into high-wear applications, industries have minimized equipment downtime, reduced operational costs, and improved overall efficiency. Components last significantly longer, which means less frequent replacement, fewer disruptions, and enhanced productivity.

For example, mining companies have reported 30-50% longer equipment life when switching from traditional steel to Rockstar 450, dramatically reducing maintenance schedules and costs.

6. Conclusion

The Rockstar 450 Plate is not just a product—it’s a strategic upgrade for industries battling extreme wear. With its unmatched durability, toughness, and efficiency, it directly addresses the challenges of abrasion-heavy environments. If you're looking to cut costs, reduce downtime, and maximize operational reliability, Rockstar 450 is a smart, long-term investment.